November 10, 2013, by Brigitte Nerlich

From making to shaking: The new world of ‘4D’ printing

I haven’t written a blog about a novel scientific development for a while, so when I read about 4D printing in New Scientist at the weekend, I thought the time had come to get to work again. I had heard about this new way of ‘making’ objects before but had not really looked into the ins and outs of this emerging technology. I had also heard, of course, about 3D printing, and before that had engaged for at least 40 years in 2D printing myself. So before we come to 4D printing, a quick word on 3D printing.

3D printing

According to Wikipedia 3D printing is “Additive manufacturing or 3D printing is a process of making a three-dimensional solid object of virtually any shape from a digital model. 3D printing is achieved using an additive process, where successive layers of material are laid down in different shapes.3D printing is also considered distinct from traditional machining techniques, which mostly rely on the removal of material by methods such as cutting or drilling (subtractive processes).”

People probably remember the controversial case of a gun being 3D printed, but only very recently did a firm in the US announce that it had printed a 3D metal gun. So, 3D printing is advancing quite fast. A few days ago there was an announcement that 3D printing could be used to print human cells/tissue, which could replace the need for animal testing – a more benign use of this technology.

You can buy 3D printers for your own use now and you can choose between a wide variety of 3D printers; some are even available on eBay.

4D printing – time, change and self-assembly

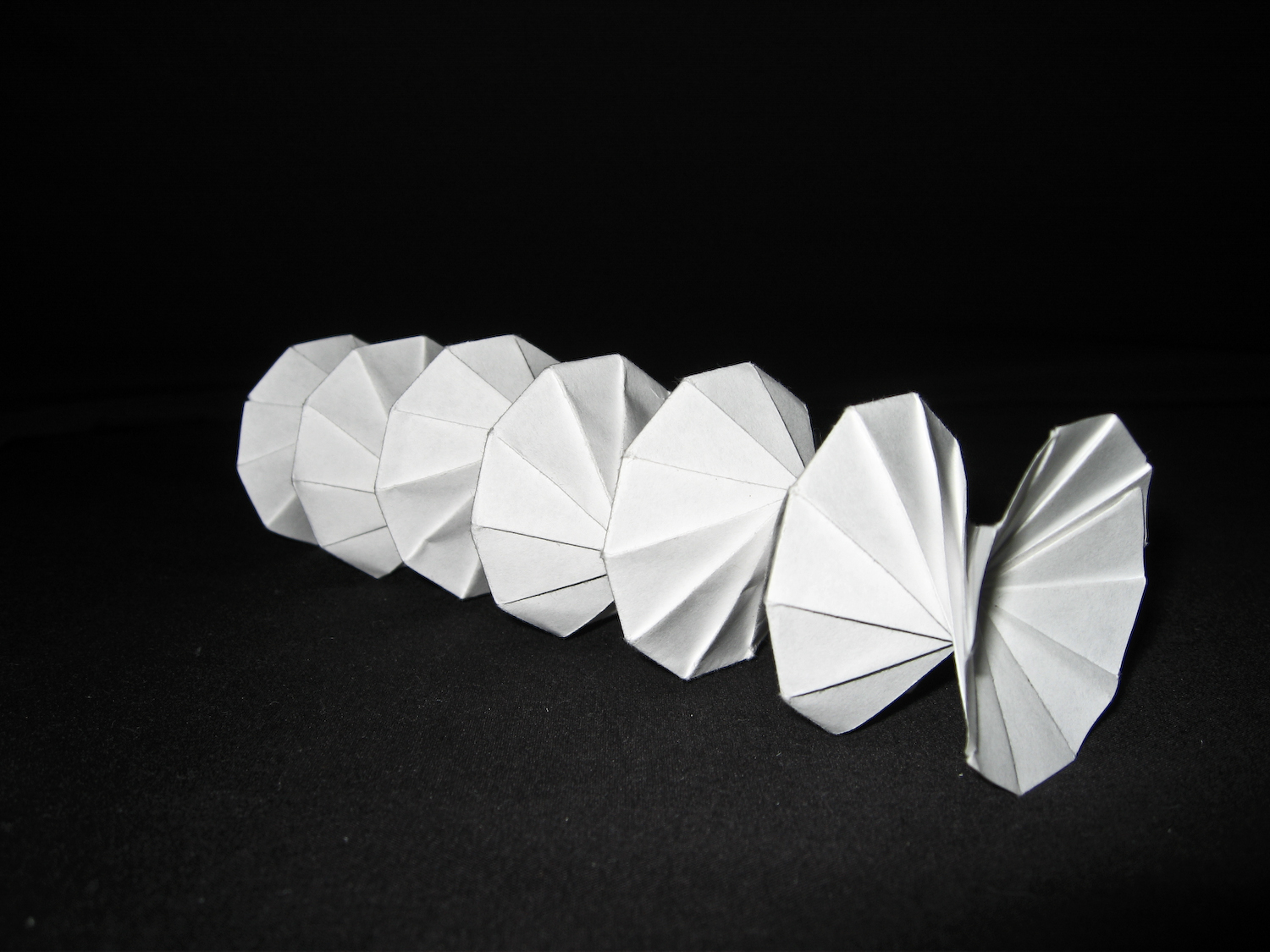

So, 3D printing is quickly becoming old-hat, commonplace and perfectible. However, it also has limitations. How, for example would you print a house, which would, at present, require a house-sized 3D printer? This is where 4D printing comes in handy, in the form of what one may call dynamic origami.

The computer scientist Skylar Tibbits, interviewed by New Scientist for its 9 November edition, talks about ‘Hyperform’ instead. This is a project in which they “use mathematical programs to fold objects so that you can assemble them – by unfolding and snapping pieces into place intuitively – so they are much larger than the printer that made them”. But like other 4D printing processes all this is still at an early stage of development.

But what is 4D about this type of printing? One normally thinks of ‘time’ as the fourth dimension. In the case of 4D printing the focus is on change (rather than, I think, on time as such). Not only would 4D printing overcome the 3D size problem, it could potentially also be used to produce materials or organisms that change and adapt to their environments triggered by certain external stimuli (reminds me a bit of the importance of electricity in all sorts of life processes…).

Again, Tibbits has an example. He and his team worked “with Arthur Olson at the Scripps Research Institute to build a model of the polio virus. If you put the pieces of the model in a glass container, they just sit there. But when you impart some energy – shake the glass – they come together. Shake harder, and it comes apart again. You have these different states based on how much energy you put into the system; you don’t control where every piece …”. And so we have ‘self-assembly’. Shaking replaces making. Static materials become dynamic materials.

Here is a good example of this process/product, as featured in Gizmodo: “’Rather than construct a static material or one that simply changes its shape, we’re proposing the development of adaptive, biomimetic composites that re-program their shape, properties or functionality on demand, based upon external stimuli,’ added Anna C. Balazs, a chemical engineering professor at University of Pittsburgh.”

Such materials would, of course, be very useful for the military, but they might also have more peaceful and benign uses, when developing, for example, novel forms of cheaper renewable energy. As Tibbits points out in another interview: “That functionality could make it possible (for example) to print a photovoltaic panel in a flat shape, expose it to water to cause it to fold up for shipping, and then expose it to heat to make it fold out to yet another shape that’s optimal for catching sunlight.”

What’s in a name?

Now why call this 4D printing? Whey not dynamic origami for example? There was a bit of debate about the name 4D printing on Gizmodo, and one of the participants suggested that a better name might be ‘Mighty Morphing Power Printer’. I have to say, I rather like that! It’s less confusing than 4D printing.

The next frontier

However, ‘Mighty Morphing Power Printer’ does perhaps not fit into the linear narrative of technology development, from 2D to 3D to 4D … . And, of course, 4D printing is called by some ‘the new frontier’. There are all sorts of new frontiers involved in 4D printing, in terms of time and space, from now to the future and from the nanoscale to skyscrapers, but most importantly from peaceful to militaristic applications.

If we want ‘upstream engagement’ with this emerging technology, this is the time to start.

Image: Spring Into Action, designed by Jeff Beynon, made from a single rectangular piece of paper, Wikimedia Commons

Please visit the first website dedicated to 4d printing.

This website (http://www.4dprinter.net/) looks fascinating! Thanks for pointing me to it.

This report focuses on the global 4D Printing status, future forecast, growth opportunity, key market and key players. The study objectives are to present the 4D Printing development in United States, Europe and China.

For More Info : http://bit.ly/2DAt0eY