August 13, 2013, by Graham Kendall

What is Food and Bioproduct Processing Research?

In this What is? series, we invite experienced researchers to write about their area of research, but in more general terms than they might normally do.

This article, entitled What is Pharmaceutical Nanoemulsion?, is written by Prof. Chung Lim Law

If you would like to contribute, then please let me know (Graham.Kendall@nottingham.edu.my) and we can discuss how best to go about it.

Anybody wishing to contact the author of this article should go to about the author.

What is Food and Bioproduct Processing Research?

Food and Bioproduct Processing research covers a wide range of research areas, ranging from food and bioproduct material, processing, science, engineering, quality to safety. Each of these topics are wide in scope and may encompasses the following aspects:

- process efficiency

- enhance product quality

- extending shelf-life of fresh and processed food products

- engineering properties of foods

- food physics and physical chemistry

- measurement of processing parameter and quality attributes

- process control

- modelling and optimisation

- packaging

- storage and distribution

- design and production of novel foods

- food service and catering

- design and operation of food processes, plant and equipment

- economics of food engineering

- reaction and transformations

- separation

- engineering for food safety, hazard analysis

- hygienic design and manufacture, product safety

- good manufacturing practice

- transport phenomena

- heat and mass transfer in single or multiphase systems

- handling of materials

- food chemistry, biochemistry, microbiology and nutrition.

Food and Bioproduct Processing Research Priority in UNMC

Obviously, the research group in UNMC would not be able to cover all the topics mentioned above, but mainly focus on extending shelf life of a bio-origin product without the use of chemical preservatives while focusing the retention of bio-active ingredients in the processed products. Meanwhile, the research group in UNMC also focuses on the design and invention of new machine for the research focuses mentioned above.

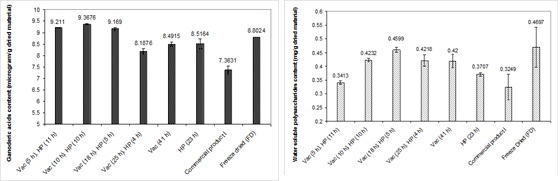

Figure 1: Retention of crude ganoderic acids and polysaccharides in dehydrated gonoderma mushroom (Source: Ching & Law, 2013 & Chin & Law, 2010)

Some of the research findings discovered by UNMC Food and Bioproduct Research

Dehydration of bio-origin product is necessary to prolong the shelf life of the product. In UNMC we attempted various dehydration methods for processing of ganoderma mushroom and examined the retention of crude ganoderic acids and polysaccharides in the dehydrated ganoderma mushroom. Figure 1 shows the results of the retention of bio-active ingredients.

Figure 1 reveals that conventional hot air drying and sun drying (commercial product) give low retention of bio-active ingredients, due to the fact the ingredients are sensitive to high temperature. However, other dehydration methods such as vacuum drying low temperature drying (HPD) are suitable for maximizing the retention of these ingredients. The retention of the ingredients is comparable to freeze drying which is touted as the best drying technology. However, its operating and capital costs are the highest render it not widely used in the food processing industry.

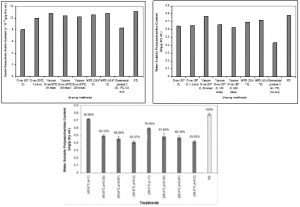

Further, we also found that a single stage drying method could not retain multiple bio-active ingredients. This has driven us to investigate the possibility of using hybrid drying method and multistage drying methods to process the material. Figure 2 shows the results that we obtained.

The results reveal that using a proper combination of hybrid drying method, we could obtain a retention that is higher than freeze drying.

Figure 2: Retention of crude ganoderic acids and polysaccharides in dehydrated gonoderma mushroom using hybrid drying and multistage drying methods (Source: Ching & Law, 2013)

References

- Siew Kian Chin & Chung Lim Law. 2010. Product quality and drying characteristics of intermittent heat pump drying of Ganoderma tsugae Murrill. Drying Technology, 28(10-12): 1457-1465. DOI: 10.1080/07373937.2010.482707.

- Siew Kian Chin & Chung Lim Law. 2013. Maximizing the retention of ganoderic acids and water-soluble polysaccharides content of Ganoderma lucidum using two-stage dehydration method. Drying Technology, in press.

Where do we publish?

- Journal of Food Engineering

- Food and Bioproduct Processing

- Food and Bioprocess Technology

- Drying Technology

- Biosystem Engineering

Want to know more?

- For drying related literatures, readers may get free e-books from this website: http://serve.me.nus.edu.sg/arun/E_books.htm

- The UNMC research group also contributes a number titles in this project

About the Author

Chung Lim Law is a Professor of Chemical and Process Engineering who works in the Industrial Drying, Food and Bioproduct Processing Research Group. He is a professional engineer registered in Malaysia, a chartered engineer and chartered scientist registered in the UK, a Fellow of the Institution of Chemical Engineers, Higher Education Academy, a Corporate member of the Institution of Engineers Malaysia, an Associate Fellow of the ASEAN Academy of Engineering and Technology. He published widely in Drying Technology, as well as other areas related to food and bioproduct processing.

He has over 15 years experience in fluidized bed technology and drying technology, both in industry and academia.

Chung Lim is currently based on the University of Nottingham Malaysia Campus (UNMC) where he is the Associate Dean of External Affairs of Faculty of Engineering and Academic Champion of the Food and Bioproduct Processing Research Priority Group.

Contact details:

- Webpage: http://www.nottingham.edu.my/Engineering/Departments/Chemenv/People/chung-lim.law

- EMAIL: Chung-Lim.Law@nottingham.edu.my

No comments yet, fill out a comment to be the first

Leave a Reply