March 8, 2016, by Brigitte Nerlich

3D printing with atoms: Beginning a story

A while ago Phil Moriarty published a post here on the ‘Making Science Public’ blog to announce a new project in which we are both involved. He talked about ‘impact’, or rather, the ‘non-impact’ type public engagement work we want to do. The project deals with Mechanochemistry at the single bond limit: Towards deterministic epitaxy. Or for short: 3D printing with atoms. If you want to know more about the technicalities of this type of printing, there is a nice Sixty Symbol Video where Phil talks about all this. A good summary of one of Phil’s lectures on the topic can be found on the Nottingham Science Blog.

A while ago Phil Moriarty published a post here on the ‘Making Science Public’ blog to announce a new project in which we are both involved. He talked about ‘impact’, or rather, the ‘non-impact’ type public engagement work we want to do. The project deals with Mechanochemistry at the single bond limit: Towards deterministic epitaxy. Or for short: 3D printing with atoms. If you want to know more about the technicalities of this type of printing, there is a nice Sixty Symbol Video where Phil talks about all this. A good summary of one of Phil’s lectures on the topic can be found on the Nottingham Science Blog.

As part of the project we want to publish a graphic novel depicting life in the labs in which the research is being carried out, the people involved, and the concepts, theories, and equipment used to make it happen.

Meeting the team

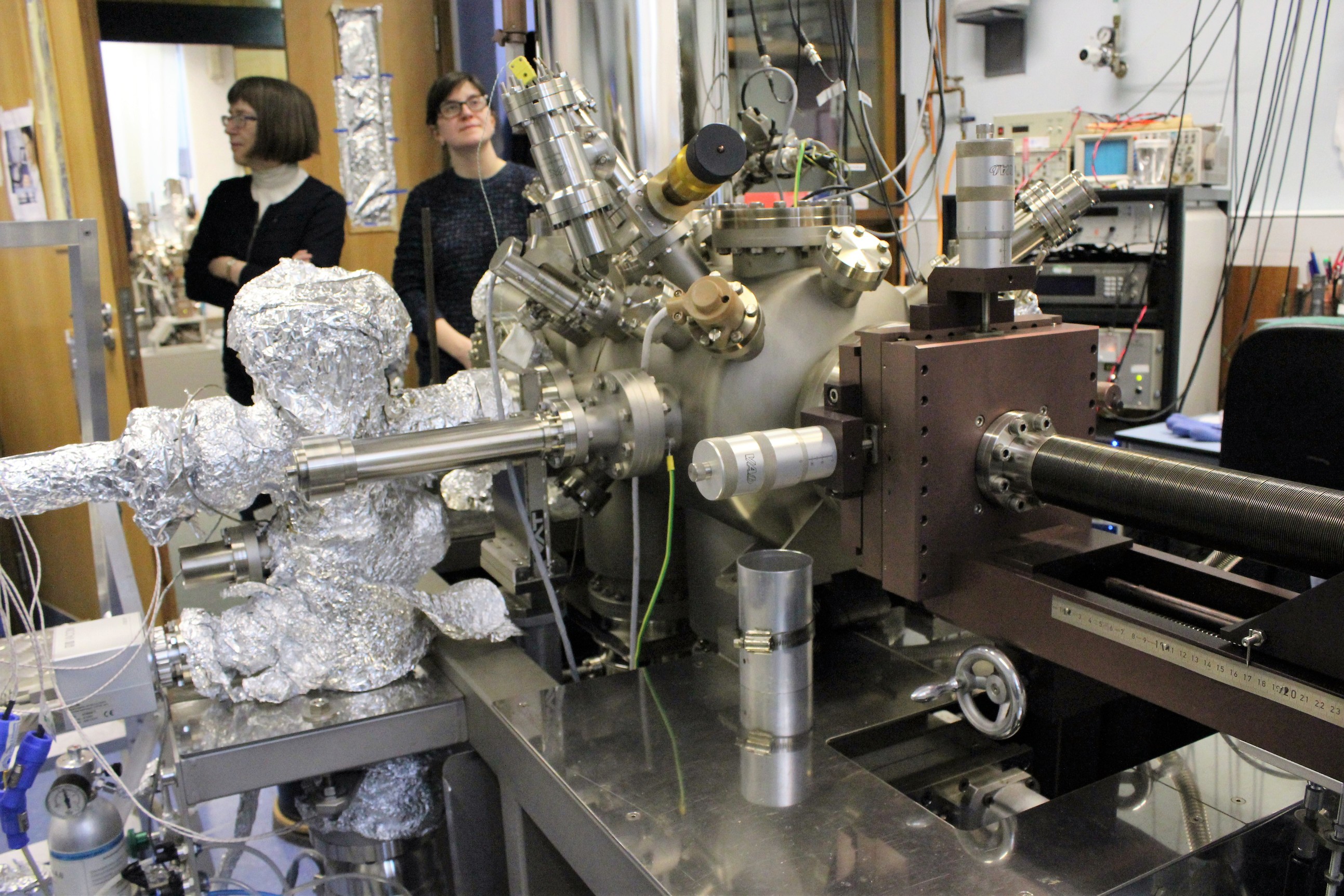

A week ago Phil and I met up for the first time with our two collaborators, a script writer, Shey Hargreaves, and Lis Groenveld, an artist. Lis brought her camera and took copious amounts of photos of big and small scanning probe microscopes (SPMs) from all angles, so she could draw inspiration from these for her drawings. She has allowed me to use some of her photos in this post.

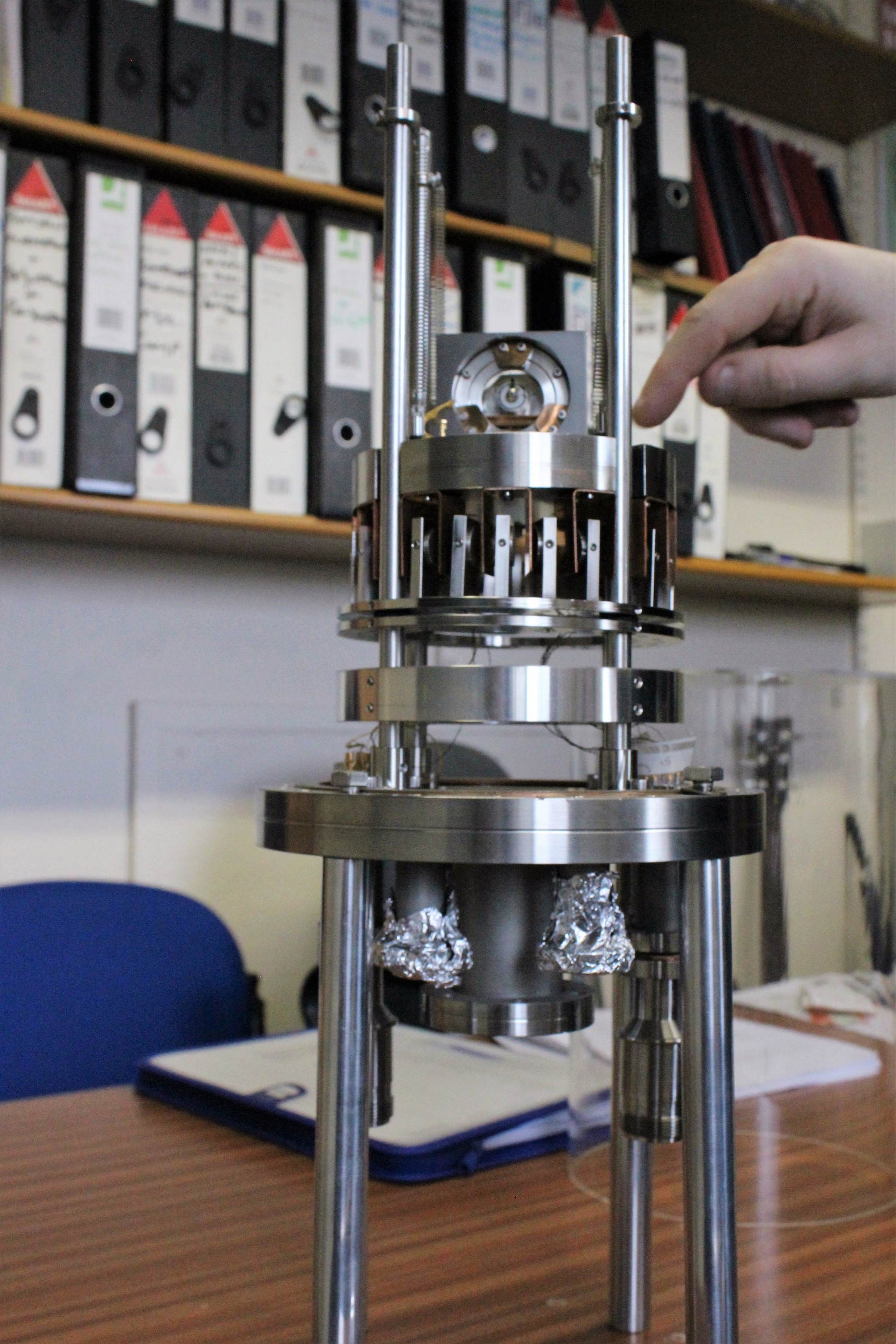

During the morning, Shey and I visited some of the labs (see photo above), and Shey interviewed a number of PhD students and postdocs. T hey all use various types of SPMs for their projects, many focusing on trying to manipulate atoms. One alumnus of the group, Julian Stirling, even built an SPM (with his project partner) when he was an undergraduate (see photo on the right).

hey all use various types of SPMs for their projects, many focusing on trying to manipulate atoms. One alumnus of the group, Julian Stirling, even built an SPM (with his project partner) when he was an undergraduate (see photo on the right).

Shey asked questions about what work the scientists did, why it was important to them and why they chose to do a PhD, in short, become a scientist. We heard some fascinating stories, which will inform Shey’s script in the future.

Enthusiasm, engineering and expertise

What struck me most was people’s passion and enthusiasm, not just for the science they were doing, but also for communicating their science. The other thing that I noticed was that all the researchers knew that they could not promise instant results, insights or impact. They very much appreciated that their work takes time, their time and many other people’s time. Their overall aim was to understand how things work at the nanoscale.

As part of this, they had to make their equipment work! It was interesting to see how they had acquired expertise in what one might call mechanical and electrical engineering alongside maths, programming, chemistry, physics etc.

The SPMs that we looked at operate under ultrahigh vacuum (UHV) conditions which reduces contamination of the samples used. To achieve good images with a UHV SPM a lot of things need to be in place. I just remember two. To isolate the SPM from vibrations (especially useful at this very moment, as a lot of building work is going on near the physics building) it stands on pneumatic legs that dampen vibrations. To achieve UHV (with a vacuum comparable to that found in space), aluminium foil is wrapped around the UHV system and a ‘bakeout’ process is carried out where the entire UHV system is heated to 150 C for a few days. This d rives off the water that is adsorbed on the inner surfaces of the UHV system and when everything is cooled down, the majority of the water is gone and a very low pressure results.

rives off the water that is adsorbed on the inner surfaces of the UHV system and when everything is cooled down, the majority of the water is gone and a very low pressure results.

I bet I haven’t quite written this up correctly, but I want to emphasise that nanoscience progresses in part by tinkering with machinery, by getting to know it quite intimately. One of the scientists actually spoke of ‘Stockholm syndrome’. He feels really quite attached to the machine he has so lovingly coaxed into producing atomic scale images. On the day we visited, one of the SPM systems had broken down and the researchers were in the process of nurturing it back to life. Over time, they have acquired a host of different types of expertise about what works and what doesn’t for that particular machine.

The other thing that struck me was that although the aim of using the probes was to see things at the nanoscale (and a nanometer is a billionth of a meter) or even (our ultimate goal) to move things around or build things on that scale, some of the instruments and actions used seem to be less than delicate. For example, to ‘clean’ the tip of the STM you apparently ‘bash’ it about. To manipulate the samples a ‘wobble stick’ is used which looks less than delicate (see photo). I hope that all this will become a lot clearer to me over the course of the project and when I have more time to listen, watch and learn.

to be less than delicate. For example, to ‘clean’ the tip of the STM you apparently ‘bash’ it about. To manipulate the samples a ‘wobble stick’ is used which looks less than delicate (see photo). I hope that all this will become a lot clearer to me over the course of the project and when I have more time to listen, watch and learn.

Nanoscience and comics

We also talked with the nanoscientists about science comics and found that most associate science comics with xkcd. Some also mentioned The Big Bang Theory. There is certainly a gap in the market here for depicting an emerging science in its ordinary surroundings. The graphic novel that Shey and Lis are writing about 3D printing with atoms will be a great way to begin to fill this gap. However, we are not alone. There is an increasing interest in ‘discovering science through comics’. So there will be opportunities to learn from others.

One thing needs stressing here: Our graphic novel/comic is supposed to tell readers how real nanoscience is being carried out, not how we imagine nanoscience to unfold – similar to the ethos of the Sixty Symbols videos to which Phil contributes. It will therefore be quite different to a long tradition of nano stories, video games and comics which have contributed to the visual construction of nanoscience in popular culture, and where we encounter nanobots, nano submarines and fantastic voyages, superheroes using nano-super-weapons, and much more. You won’t find any of those in Shey and Lis’s story.

I think a blog series on the journey of discovering how the equipment and technology works would be interesting all by itself. Regarding a graphic novel, you may want to talk to the experts at http://www.page45.com

I wonder whether the “industrial” procedures used in some cases are in direct proportion to the uniqueness (homebuilt-ness?) of the equipment….

Wow, I’ll talk to Shey and Phil about that!