October 25, 2019, by Katie Andrews

Nottingham technology, Pulse, proposed as new alternative test in UK government consultation for construction industry

A new airtightness test for buildings, developed by the University of Nottingham, has been mooted in a government consultation as an alternative test to be added to the construction process.

The testing of airtightness is needed to help establish and minimise the infiltration of cold air into buildings and the loss of heated air out through gaps, holes and cracks in the building fabric.

Testing is also required in case the building is too ‘tight’, as too little ventilation can lead to poor indoor air quality, which in turn can cause adverse health effects for occupants.

The University of Nottingham’s Faculty of Engineering pioneered the novel and easy to use test, called Pulse, which has been developed over 14 years and was recently commercialised with industry partners. The team worked with tech start-up Build Test Solutions (BTS) and a consortium of specialists and academics in the energy efficiency industry, including The National Energy Foundation, Absolute Air and Gas and Elmhurst Energy, leading to the technology being commercially licenced to BTS.

Government consultation

The Future Homes Standard consultation which covers both Part L (conservation of fuel and power) and Part F (ventilation) was released on the 1st October 2019 and has presented a number of changes to existing regulations.

The consultation includes a proposal that all new dwellings should have an air tightness test (effectively removing the existing sampling approach), but it also seeks views on introducing the low pressure Pulse technology as an alternative method of air tightness testing. The Pulse technology, has been the subject of extensive field trials, product development and 3rd party verification. The inclusion within the consultation therefore represents a significant step in the journey towards delivering this particular leakage measurement innovation to the wider UK industry.

To provide a response to the consultation about Pulse, please refer to Questions 53, 54, 55 and 56 via the following online form. To see the full consultation, click here (references to Pulse on page 54 and Annex E, page 80 for response template).

Why is Pulse being proposed?

Pulse is a new test method that is complimentary to the existing blower door fan pressurisation technique. Each offer a specific range of features and benefits to the operative, with Pulse specifically developed to enable the measurement of air leakage directly at pressures representative of ordinary conditions – typically 4 Pascal (Pa), whereas a blower door fan will usually test in the 30 to 60 Pascal range. This in turn provides insight into the background ventilation rate of a building, helping to assess the suitability and likely performance of the ventilation system specified or already installed. This measurement of air leakage directly at 4 Pascal is also particularly important where accurate whole building energy performance calculations are required for determining energy demand, CO2 emissions and running costs, or where risks such as poor ventilation system performance or associated matters such as poor indoor air quality or overheating are a high priority.

Presently, a lower air leakage limit of 1.5 m3/h/m2@50Pa is proposed within the consultation for the system but the University of Nottingham and Build Test Solutions are confident that this cap can be lifted, with adjustments to the product having now been made. A report has also been compiled, which demonstrates that the Pulse system is able to reliably measure very airtight certified Passivhaus properties with air change rates of between 1 and 0.5 m3/h/m2@50Pa.

Using Pulse

The current industry-standard ‘blower door’ technique requires sealing off an external doorway with a fan and blowing air in or out to create a high pressure difference between the inside and outside, which is not representative of normal use.

The blower door, which has been used since the late 1970s, typically takes 15-30 minutes to complete, requires a trained operative and as such is usually only used at completion stage, when it is often too late or difficult to carry out full remediation.

Recent studies in the UK have shown large discrepancies between different blower door operatives testing the same buildings, leading to concerns over reliability.

The PULSE technique is quick and easy enough for construction workers to perform themselves multiple times prior to completion, saving time and test costs later on.

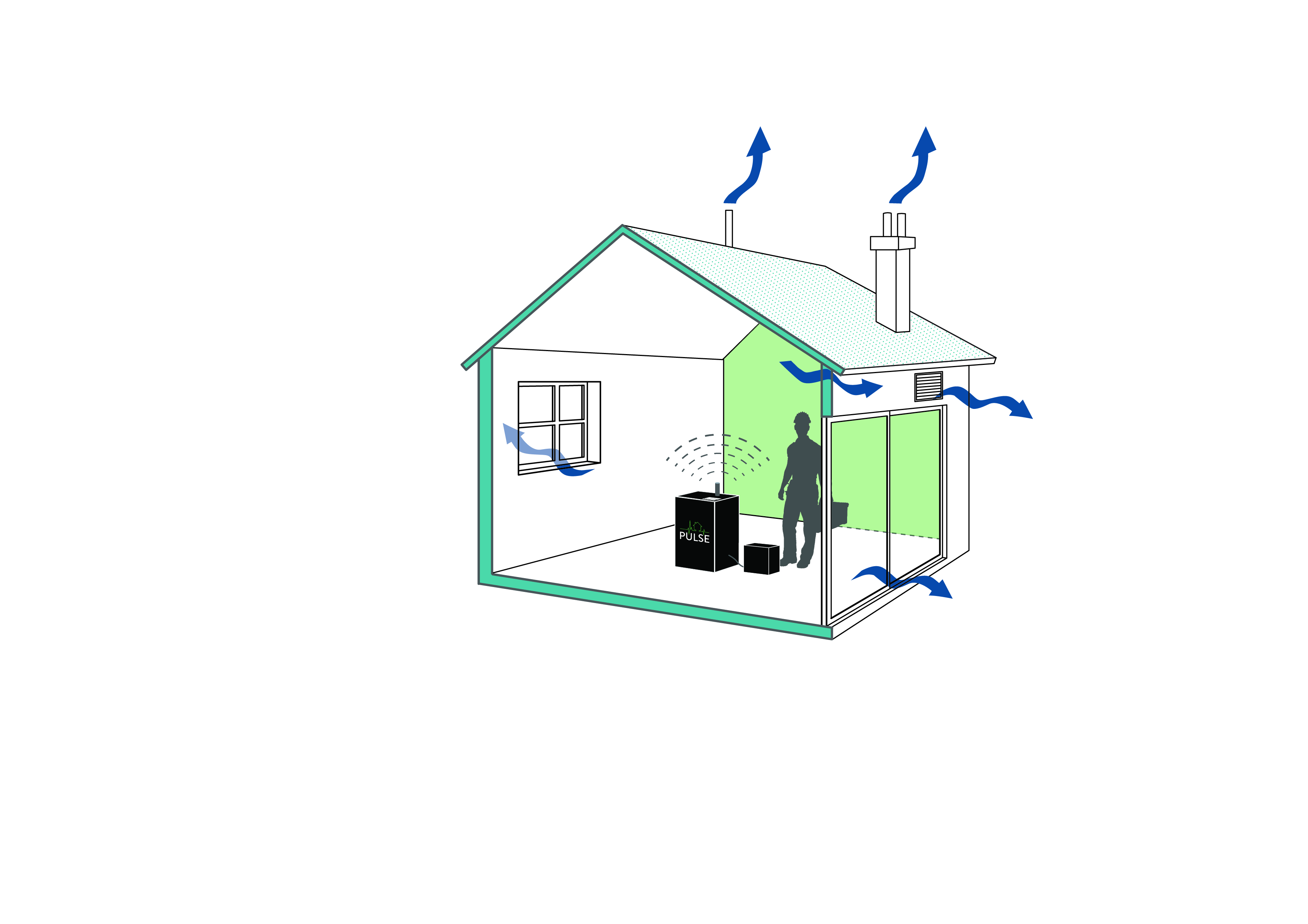

The PULSE testing unit is self-contained and has no need to penetrate the building fabric or block up any doorways.

The Pulse measurement itself is dynamic and completed in a matter of seconds. For this reason it is not possible to use the method to identify air leakage paths. It is, however, quick and simple to retest and Build Test Solutions also offer a Leak Checker product as a complimentary low cost window mounted fan to enable further diagnostic work to be carried out when required.

Although early days in terms of unlocking the market, Build Test Solutions have also been working with the Manufacturing Technology Centre, the University of Nottingham and other key stakeholders to redesign Pulse in response to industry feedback about its portability when used on live construction sites. The package comprises a newly designed air receiver unit as shown in the illustration, a small control module and a compressor which together can all be readily carried by a single person.

Next Steps

Pulse presents a new and exciting means of measuring the air leakage characteristics of buildings under ambient conditions. It is hoped by the inventors that this will provide new insights into the performance of buildings and their associated ventilation systems as well as new opportunities for the market. Rather than a direct replacement to the blower door fan pressurisation technique, Pulse stands to offer a solution for providing new metrics as well as an improved means of testing other types of buildings and enclosures such as existing homes, non-residential buildings (through tethering of multiple Pulse devices), laboratories, health care environments and gaseous fire suppression facilities such as data centres, server rooms and stores.

BTS believe that, for those responding to the consultation, there’s little to lose and potentially much to gain from providing your support for this UK based innovation.

No comments yet, fill out a comment to be the first

Leave a Reply