June 8, 2015, by Lindsay Brooke

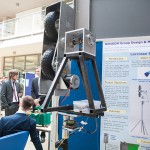

Boats, planes and robots – all in a day’s work for a mechanical engineering student.

This year’s University of Nottingham Mechanical Engineering Design and Make Exhibition features prototypes that pedal bicycles, machines to help clean your room, unmanned aerial measuring systems and an autonomous sail boat.

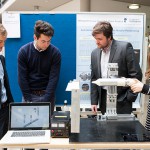

Students on the MEng Mechanical Engineering courses work in groups of four to develop a prototype or product through the “professional” design cycle from ‘Statement of Requirements’ to evaluated prototype. There are industry style review gates at key points in the project and professional management approaches to time management, budgeting and risk. Many of the projects have an industrial customer.

Here are a few examples of what’s on display

Robotic cyclists

You might think riding a bike is easy but if you work out all the clever things your brain does just to maintain balance and direction you’d be surprised. In this project a group developed an autonomous bike that uses sophisticated measurement and control systems.

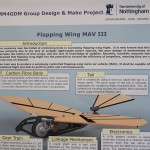

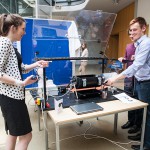

The IMechE UAS (unmanned aerial system) challenge

Two groups of students have designed and built an entry for the IMechE UAS challenge. The system is required to fly between altitudes of 100ft and 400ft over a course of approximately 2km with flight duration of up to two minutes. During this flight the aircraft is expected to navigate a series of GPS waypoints and deliver two 1kg packages of flour in separate drops to a target on the ground. Additional points are awarded for aircraft that incorporate a visual system that can identify a letter of the English alphabet within a 2 x 2 metre box in the drop zone.

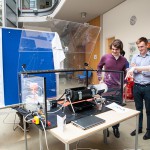

Unmanned aerial vehicle for taking measurements

There are many applications where you need to be able to take measurements from something large and complex in shape. This idea uses an unmanned quadcopter carrying a laser range finder and imaging sensor to do the job.

Radical approach to a more efficient internal combustion engine for cars

Students have developed a prototype “no-crankshaft engine” that uses linear motion to generate power. It has the potential to be far more efficient than the conventional engine.

Generating electricity for the developing world using thermoacoustics and a bi-directional turbine

Thermal energy can be converted in acoustical energy and this can be turned into electricity using a bi-directional turbine. In this project a bi-directional turbine has been developed that generates energy from a 50W loudspeaker that simulates a thermoaccoustic engine.

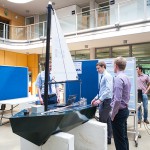

Autonomous sailboat for Cunard Transatlantic challenge

Sailing is a pretty skilful job and the idea of an autonomous sailboat is both ambitious and exciting. Students have developed the control system to sail a boat developed by a project group last year. There are systems for measuring wind speed and direction and then setting the sail and controlling the rudder. The boat’s been tested on calm inland waters but not yet on the Atlantic itself!

Producing alloy powders for 3D printing

One of the up and coming 3D printing methods is selective laser melting. For this you need special alloyed powders and the process is called satelliting because the smaller particles are bonded to larger particles around the surface. The developed mixer has been shown to work with iron oxide and salt as a cheap demonstration of capability. More expensive materials (such as Titanium boride) will be bonded in future use.

Want to know more?

Schools and special guests will be attending the event. But if you want to go along it is taking place in the Engineering and Science Learning Centre on University Park from today – 8 June – until the end of Wednesday 10 June.

No comments yet, fill out a comment to be the first

Leave a Reply