October 21, 2015, by Sara Roggia

INNOVATE and AVIO AERO: Bringing Industry and Academia Together

INNOVATE is a University of Nottingham European-funded doctoral training program that offers a researcher the opportunity to study for a PhD as well as spending a minimum period of six months in a company. Here INNOVATE Early Stage Researcher (ESR), Sara Roggia, talks about her role as part of the INNOVATE project and her secondment at Avio Aero in Italy.

Working within industry is an invaluable opportunity for PhD student. It’s a common idea to consider the research world as distant from the business reality. More often PhD students are focused on their own research work without considering the feasibility and the potential real-world impact of their ideas. Questions they should ask themselves include “is my idea feasible?”, “is it affordable?”, “how long would it take to be realised?” and are inquires a PhD student will never answer if they do not develop a commercial understanding of research. Industry, on the other hand, doesn’t always know what research is being invested in and which scientific direction has been chosen by the academic world. The conceivable mistake is they will keep on walking two parallel routes.

In Italy, the company Avio Aero is trying to converge the two paths. In Southern Italy, in Bari to be precise, an official collaboration was agreed between Avio Aero and Politecnico di Bari, a Technical University located in the same city. A bilateral accord was signed in 2010, in which Avio Aero gave guaranty of investing its own resources until 2020, mainly in five research areas, employing several university’s researches and PhD students for each area.

Taking advantage of the local presence of such a noteworthy university (Politecnico di Bari – First Italian University in research in the 2012 and 2013 SIR World Report (Scimago)), Avio Aero decided to develop a multidisciplinary lab, in which activities will be led by five researchers of Politecnico di Bari, with suggestions and directions provided by nine Avio Aero leading researchers. This centre is known under the acronym of EFB (Energy Factory Bari).

Avio Aero is a company that works in the field of aviation. Previously named simply as Avio, it was born in 1908, funded by FIAT group. Recently (2013), it became part of GE (General Electric) and it was re-baptised under the name of Avio Aero, because of its specific applications in aeronautics.

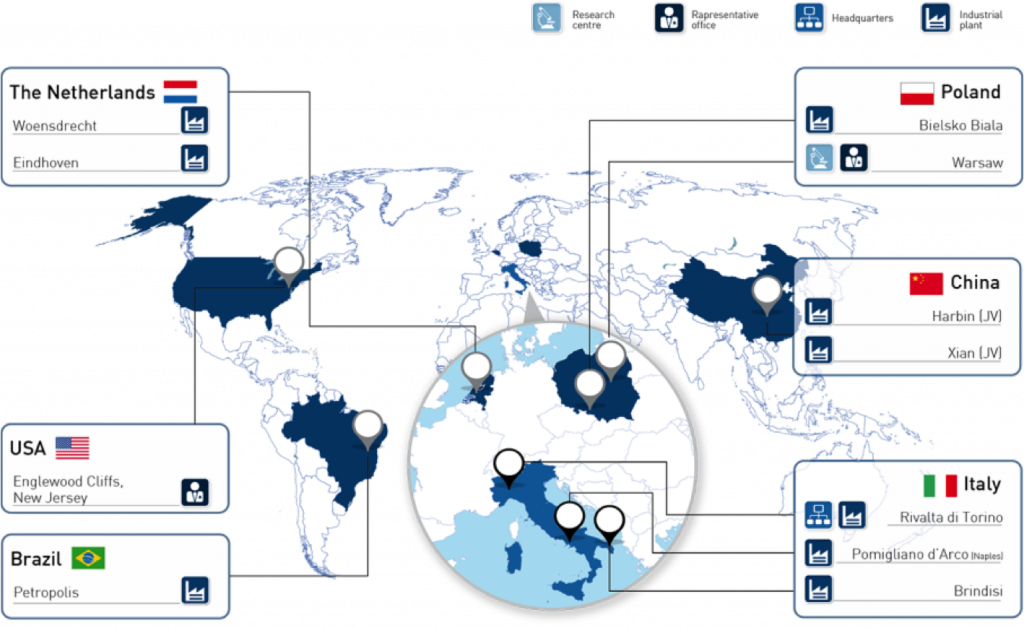

Namely, Avio Aero is a GE Aviation business, working on the design, production and maintenance of components and systems for the civil and military aeronautics industry. Nowadays, 80% of commercial aircrafts utilise Avio Aero components. Its head office is in Turin, Italy, and its production plants are spread worldwide: Netherlands, USA, Brazil, China, Poland, Italy.

One of the Italian headquarters is in Bari. Here, the proximity of Avio Aero employees to the students and researchers, inside EFB labs, enlarge the possibility of exploring additional scientific subjects.

The aforementioned five sectors under investigation are:

- High speed electrical machines;

- High Frequency Power Converters;

- Control Systems;

- Thermal fluid dynamics of machines and energy systems;

- Mechanical machine design.

The main aim is to develop new technologies and architectures for reducing aircraft weight, thereby improving aircraft performance and moving towards more electric aircraft.

The same collaborative spirit drives the INNOVATE Project, led by Professor Hervé Morvan and the Institute for Aerospace Technology (IAT), as a multidisciplinary project in which PhD students are expected to bring different expertise to the field of aerospace field in order to enhance the state of the art and find “more electric” solutions to air travel.

Both of them, Avio Aero and the IAT, understand the importance of having people from different backgrounds working at the same time in the same environment, creating connections and enabling a transverse flow of information between mechanical, electrical, and aerospace engineers.

Furthermore, they equally appreciate the importance of collaboration between research and industry. Avio Aero built a dedicated conjoined lab in Bari whereas the IAT invited companies to be part of the INNOVATE project.

Several companies, during the development of the INNOVATE program, were chosen in order to collaborate with each of the INNOVATE Early Stage Researches (ESR). Avio Aero was selected as industrial partner for me, ESR9 (Sara Roggia), working on ground operation electrical systems, i.e. electric motors for Green Taxiing (GT) application.

When he first met the INNOVATE Team, Professor Francesco Cupertino (Deputy Director of department of Electrical and Electronic Engineering of Politecnico di Bari and Avio Aero INNOVATE delegate), he could immediately see the industry-focus of the INNOVATE Project. He took part at the INNOVATE Launch event where our first team project – the development of two unmanned UAVs – was showcased.

Prof. Cupertino (Avio Aero representative) and other industrial partners attending INNOVATE Launch Event.

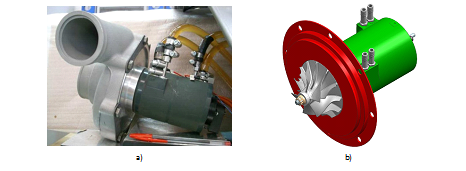

A similar project is now ongoing in Avio Aero labs. Named MALET, this activity regards the development of hybrid propulsion system for UAV’s application. Specifically, an aeronautic propulsion system, in which turbines and compressor are electrically actuated, will be designed and built.

I am now spending my secondment in Avio Aero – Bari, working on the experimental part of GT Project.

Avio Aero gave me the possibility of establishing a test rig in order to develop the control of a conical actuator (based on principle of sliding rotor) that will be utilized for GT application.

EFB Labs: several test-rigs designed for standard motor testing and experiments on high-speed machine for propulsive applications.

At the same time, due to the great interest of Avio Aero in high speed electrical machines, I have been involved in several on-going studies regarding this topology of motors. The aerospace industry is investing a lot of resources in this kind of motors, because of the advantages they could offer. The possibility to remove mechanical gear, meaning less noise, and the chance to have a smaller motor size for a given power are just two such advantages.

Avio Aero and Politecnico di Bari are distinguished in terms of the investigation and publication about this topic. Together with “Politecnico di Torino” (a worldwide recognized university in the field electrical machines, strongly connected with both “Politecnico di Bari” and The University of Nottingham), they developed a design tool for High Speed Synchronous Reluctance machines (SyRe), thereby contributing to the development of state-of-the-art aerospace technologies.

Having looked at the above mentioned initiatives, it is easy to see that there are impressive quantities of industrial projects in which PhD students can easily fit, contributing to the development of the actual technologies whilst improving their capability for doing research. Fortunately, things are evolving in this sense thanks to such kinds of collaborations, in which both Avio Aero and the IAT strongly believe.

Photo Credit: Chiara Stomati

No comments yet, fill out a comment to be the first

Leave a Reply