October 5, 2020, by Jo Gregory

The goal is a greener future: An interview with Dr Omar Aboelazayem

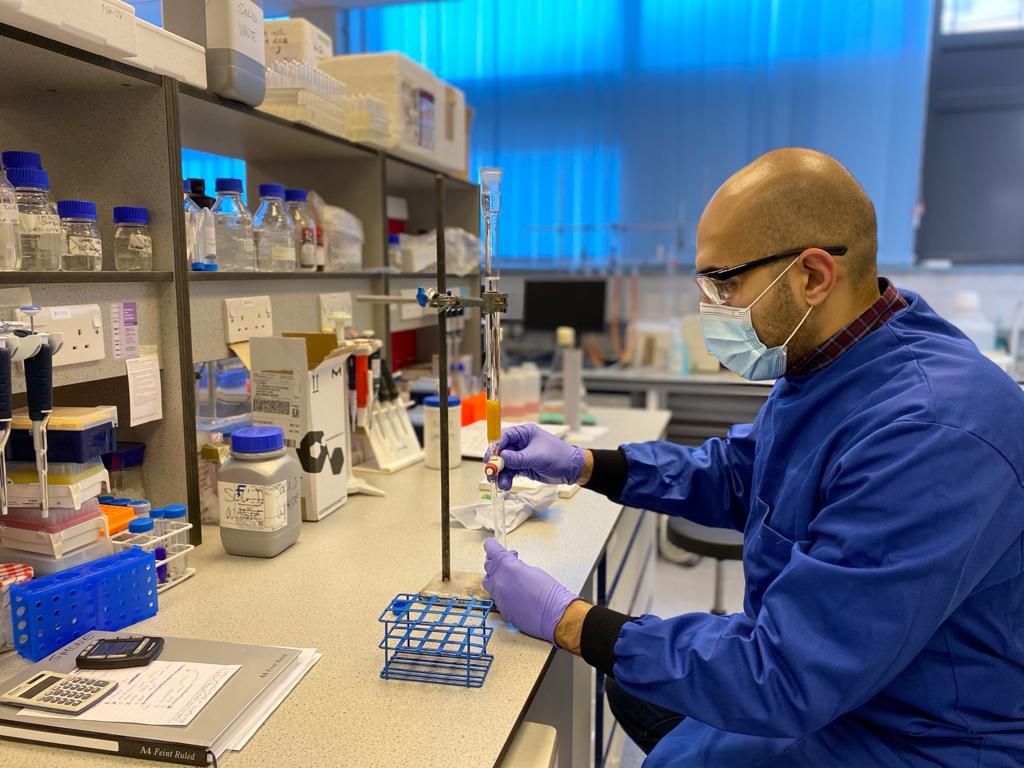

Dr Omar Aboelazayem joined the University of Nottingham in November 2019 as a Technical Specialist in Sustainable Chemical Processing in the Department of Chemical and Environmental Engineering aligned to the Green Chemicals Beacon. In this interview, he talks to Jo Gregory about his inspirations, his approach to work during the pandemic and how his research is tackling global challenges.

Could you tell me a bit about your research career?

As a research intern at Universitat Rovira i Virgili in Tarragona, Spain, I worked on a project which looked at producing biodiesel from sewage sludge. This inspired me to explore research focused on converting waste into biodiesel and under the supervision of Professor Nour El-Gendy at The British University in Egypt (BUE) my research graduation project looked at biodiesel production from waste cooking oil (WCO) using eggshells as a catalyst. I found that using household WCO was more effective than industrial WCO having observed difficulties in converting the high acidity industrial WCO into biodiesel using conventional methods.

While working as a teaching assistant in the Chemical Engineering Department at BUE, I started my PhD research in Professor Basu Saha’s research group at London South Bank University (LSBU) in 2015 under joint supervision with Professor Mamdouh Gadalla from BUE. My research focused on the valorisation (reusing, recycling, composting) of high acidity Egyptian WCO collected from local industries. We successfully developed a sustainable approach for high acidity WCO conversion into high-quality biodiesel using supercritical methanolysis. I then used my preliminary PhD results to assist my supervisors in successfully applying for a Newton Institutional Research Fund between the UK and Egypt through the British Council and we were granted a fund for my research project. I also worked as Postdoctoral Research Assistant at LSBU where I worked with new students who developed my PhD findings.

My research interests include but are not limited to; biomass valorisation technologies into biofuels and value-added chemicals, process optimisation and process integration.

How would you explain your research to an ordinary person?

The demand for fossil fuels (coal, oil, gas) for energy and to produce chemicals has risen dramatically along with the increasing growth of population and metropolitan industrial societies. This has led to environmental impacts including air pollution, global warming, climate change and water contamination.

My research is focused on developing sustainable, green and economically viable technologies which will convert biomass waste (made from renewable resources) into biofuels and value-added chemicals. I am aiming to provide a significant impact in the biofuels field in order to reduce the reliance on fossil fuels and allow us to have a greener future.

How does being part of Green Chemicals help you achieve your goals?

My previous work has been focused on thermochemical conversion technologies and joining the Green Chemicals Beacon is a great opportunity for me to advance my experience in biochemical processing for the production of biofuels and value-added chemicals.

The Beacon provides me with access to explore advanced research facilities in this field and being part of the technical staff has improved my technical skills. I am looking forward to making a significant contribution in the area of biochemical downstream processing.

The University of Nottingham is also providing me with an excellent opportunity for professional development. I have recently joined the Teaching and Learning Development Programme (TLDP) of the Nottingham Recognition Scheme (NRS) and successfully achieved the status of Fellow in Higher Education Academy (FHEA). I am also working towards chartered chemical engineer membership from the Institute of Chemical Engineering (IChemE).

What current projects are you working on?

What current projects are you working on?

I am currently working on a UKRI funded project in collaboration with BIOME Technologies researching sustainable bio-based monomer production processes based on a novel synthetic biotechnology platform. This will be implemented in a new generation of highly functional and biodegradable bioplastic polymers (plastics). I have a key role in supporting the research on the development of an efficient downstream process to separate the targeted monomers from the fermentation broth. I also support the teaching activities for the chemical engineering undergraduates and MSc students in the pilot-scale laboratories in my department.

How has COVID affected your research?/How have you found working from home rather than the lab during a pandemic?

As my current research is mainly lab-based work, I have considered the lockdown as an opportunity to enrich my theoretical knowledge in biochemical processing through literature. In addition, it was a good chance for me to proceed in my professional development and I achieved the status of Fellow in Higher Education Academy (FHEA) during the lockdown.

I also expanded my previous PhD work by designing an integrated approach to recovering the residual waste heat of the biodiesel process using an organic Rankine cycle, which has been recently published in Renewable Energy Journal (simulation-based work). I have also contributed to a collaborative research fund proposal with my previous PhD supervisors to be granted by the British Council through the Newton Fund Impact Scheme (NFIS) representing the Green Chemicals Beacon as an associated partner.

How did you become interested in engineering? Where do you get your inspirations from?

I grew up in a family full of medical doctors and dentists who expected me to follow them into being a doctor. However, my favourite subjects at school were mathematics and chemistry. I remember that I used to enjoy mathematics class where our teacher called me “king of math”. My high school in Jubail Industrial City, Saudi Arabia was very close to the chemical plants of the SABIC petrochemicals company. The huge and complicated processes of SABIC industries grasped my attention and curiosity and were the main reason for my decision to study chemical and process engineering.

Do you have any advice for young engineers?

Engineers are innovative problem solvers. If you are interested in figuring out applicable solutions to complicated problems, you will most likely enjoy engineering!. From my experience, engineers should be like a sponge that continues to receive information and learn new skills. Engineers require continuous learning to be up to date with the accelerated pace of knowledge.

What is your greatest career moment so far?

Being shortlisted to present my research in the House of Commons, UK Parliament as part of STEM for Britain 2018 is one of my greatest career moments. It was such an honour for me to be shortlisted as one of the best 45 researchers in the UK. It was great to present my work to the members of parliament and Fellows of the Royal Academy of Engineering. The discussion with them was very fruitful and has opened my mind to the importance of ensuring your research is feasible and economically viable. I also learnt how policy-makers and investors approach and understand academic research projects and what we should highlight to grasp their attention.

You can read Omar’s latest collaborative research article which presents an integrated approach to recover the residual waste heat of biodiesel production process via organic Rankine cycle (ORC) in the Renewable Energy Journal.

To find out more about the Green Chemicals Beacon and how our team of researchers are working to secure the low carbon economy of the future, please visit the website or follow us on Twitter @UoN_GCB

No comments yet, fill out a comment to be the first

Leave a Reply