December 17, 2020, by Jo Gregory

Super sustainable processes: making green hydrogen from waste.

Chai Lee (Jesslyn) is a Research Fellow in Sustainable Processing in the Green Chemicals Beacon and is also a member of the Sustainable Processing Technologies Group. In this interview, she talks to Jo Gregory about her research, inspirations and the importance of using sustainable processes for the generation of electricity and power.

What is your role here?

My research is focused on supercritical water gasification (SCWG) which is a process used in the production of green hydrogen. I work on the development and design of a highly efficient SCWG system as well as looking at how to optimise the whole process in order to reduce energy consumption, maximize the hydrogen yield and minimize the char formation that can cause blocking problems. I focus on using lignocellulosic biomass waste and wastewater from food and beverage industries as the feedstock of SCWG process. I also investigate feedstock pre-treatment methods before the SCWG process starts which can help to enhance biomass slurry pumpability during a continuous run, increase the biomass decomposition rate during gasification process that can lead to the improvement of gasification efficiency and hydrogen yield.

What were you working on before you started your current role?

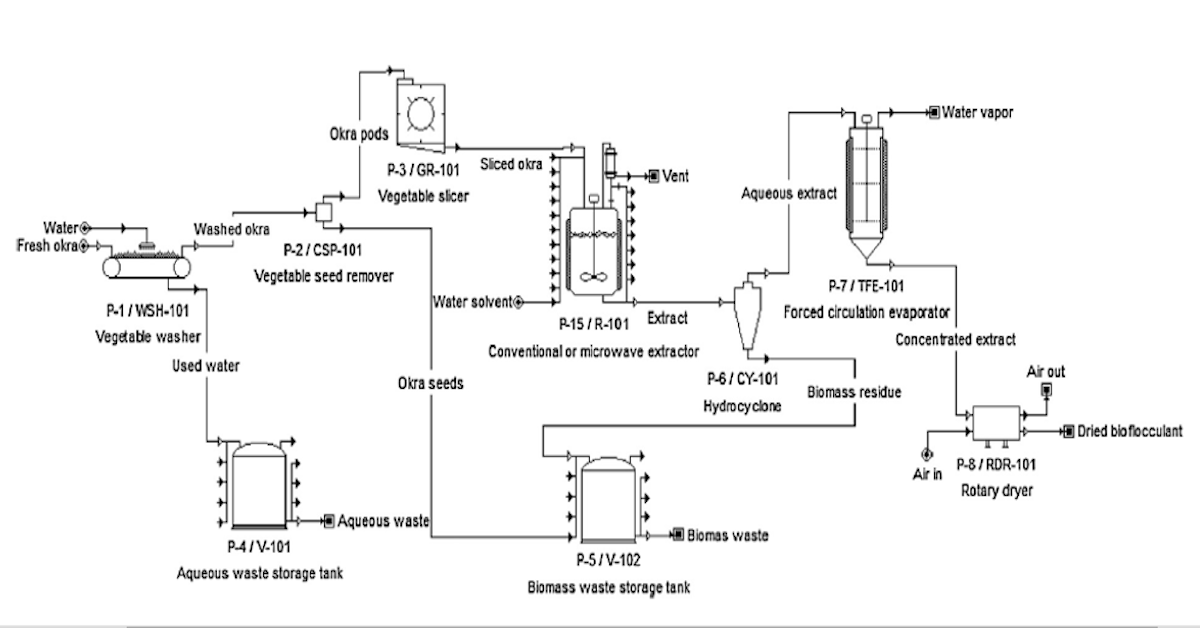

I did my Master’s degree in Taiwan and then a year’s research experience working in biological chemistry looking into the interaction between protein and cell membranes. My PhD study at the University of Nottingham was focused on the development of advance extraction methods, in particular, using microwaves to extract plant-based bio-flocculants as a sustainable alternative to chemical flocculants. Flocculants are substances which bring together fine particles in liquids and make them either float to the surface or settle at the bottom making them easier to separate. My study showed that microwave extraction can extract the bio-flocculant in a shorter time (minutes) and also generate a higher bio-flocculant yield (produce more) compared to conventional methods. I also found that the efficiency of microwave-extracted bio-flocculants is comparable to chemical flocculants. Green bio-flocculants are extracted using only water and we use these ‘green’ chemicals to treat wastewater, for example, to remove suspended solids and sludge from the wastewater so that the water can then be used again.

Image taken from Jesslyn’s article published in Chemical Engineering Research and Design 1 3 2 ( 2 0 1 8 ) 358–369

After my PhD, I worked in Hong Kong as a senior engineer in a research institute. I worked on a collaborative project between the institute and three industrial partners looking at the development and application of nanobubble technology in water and wastewater treatment. The project involved the studies of 3 systems: (1) nanobubble ozone oxidation system (10 and 50L) for the treatment of textile wastewater focusing on removal of colour and chemical oxygen demand (COD), (2) nanobubble ozone oxidation system (80L) for the sanitization of river water focusing on removal of E.coli and total bacteria, (3) continuous-mode pilot-scale (20 to 40mL/min sewage input) nanobubble-moving bed bio-reactor system for the treatment of sewage focusing on removal of COD, ammonia and total nitrogen.

It was great to have that experience of working with industry. I really enjoyed working collaboratively, finding out how we could meet their expectations and discuss how we can work together to achieve results. Having completed the project I moved to Nottingham to start my current role with the Green Chemicals Beacon.

How would you describe what you do to an ordinary person?

I use advanced technology to convert biomass waste into green hydrogens that can be used to generate electricity and power. The advantage of this technology is that it can generate hydrogen very quickly, using only water and with no chemicals involved so it’s also a sustainable process. Using waste to generate hydrogen is very valuable because it’s an alternative to the energy we generate from petroleum which is not environmentally friendly and is also finite!

How is being part of the Green Chemicals Beacon helping you to achieve your goals?

It’s so important now to find sustainable alternatives in the production and manufacture of chemicals and that’s why I want to focus my research around finding green processes which will be useful in protecting the environment. Using plant-based bioflocculants, only water as a solvent to extract the bioflocculants from the plant and working with plants instead of artificial products are all helping to make processes more sustainable.

The Green Chemicals Beacon is a brilliant way for me to get more experience in order to make a contribution. There are so many scientists and engineers here using their experience and expertise to deliver greener processes and greener chemicals and it’s so valuable for me to be able to learn more from my colleagues about what research has been done, what still needs to be done and discuss potentials for collaboration. There are also opportunities to work with industry and access to state-of-the-art equipment.

Where do you get your inspirations from?

I remember when I was in secondary school being really curious about all the things we have, why we have them and how they work. Washing machines, cookers, cars; all things that help to make our daily life much easier and inventions that came from research in the fields of science, technology and engineering. I was really interested in how this research was scaled up into mass production and so I chose to go into the science stream in school so that I could find the answers to my questions and continue my curiosity. It was really fun and interesting to know more and it just made me want to continue. What it also made me aware of how advances in technology have brought harm to the environment such as the huge amounts of carbon dioxide released in the production of everyday products as well as toxic chemicals which often end up in wastewater. So although these products have given us a lot of conveniences they have had a very negative impact, which has led to my interest in finding out how we can develop products and processes that are useful to us but also minimise impact to the environment. This is my hope!

How have you found not being able to be in the lab during the pandemic?

Well it has been challenging and I’m really looking forward to being back in the labs but it’s also been an opportunity for me because most of the research that I’ve done previously was based in the lab and I didn’t get much time to do other important areas of research such as simulation work. Simulations are really valuable for scientists and engineers in being able to predict what will happen in our experimental work. We can also use simulations to see what kind of challenges we will face when we want to scale-up the process. Working from home has been the perfect time to get experience in this area and see how simulation and experimental work can be correlated with each other.

What advice would you give to young engineers?

If you have questions follow your curiosity and find the answers. It’s really fun and really rewarding!

To find out more about the Green Chemicals Beacon and how our team of researchers are working to secure the low carbon economy of the future, please visit the website or follow us on Twitter @UoN_GCB

It is truly a nice and helpful piece of information. I am glad that you simply shared this helpful info with us. And also thank you for your detailes