February 4, 2021, by sustainablenottingham

Transforming University waste back into resources

Enva is the waste contractor partner for the East Midland’s University’s Waste Consortium (EMUWC), made up of the University of Nottingham, Nottingham Trent University, Loughborough University, and the University of Leicester. Enva recently released their first Sustainability Report, setting out their commitment and addressing the major challenges the country, and the sector, still face. Robyn Thompson, Enva’s Key Account Coordinator for the EMUWC, explains how they are turning the University’s waste into something useful.

In 2020, 318,000 tonnes of CO2 have been avoided due to Enva’s commitment to recycling and reclaiming waste materials.

Enva’s role in providing waste materials with a second life means that virgin resources that would otherwise have been consumed, can be left alone and that the greenhouse gases that are released during extraction and manufacturing of these resources can be avoided. It’s equivalent to offsetting over 96,860 tonnes of fossil fuels or approximately 743,044 barrels of oil. To put this into context, that’s around half of the oil consumed on an average day across the whole of the UK.

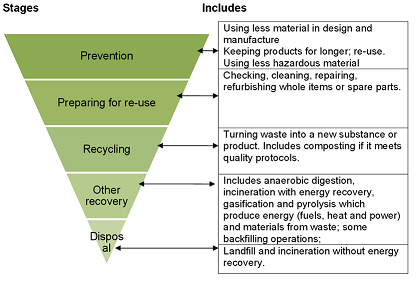

The waste hierarchy

Resource recovery and moving towards a circular economy are vital in allowing us to live and develop sustainably. Using the principles of the Waste Hierarchy, we focus on solutions that result in reuse and high value recycling of waste materials.

For example, over 99% of waste wood that Enva collect is recovered, either through recycling into new products such as panel board and animal bedding, or into renewable energy as biomass fuel. This includes the award-winning, closed-loop solution, ‘easi’ range of recycled animal beddings, providing a sustainable alternative to ‘traditional’ animal bedding.

Waste that cannot be re-used or recycled can still add value in the form of sustainable energy production and waste-derived fuels. General waste from the University is made into products, including Refuse Derived Fuel (RDF) and Solid Recovered Fuel (SRF), which are used to replace fossil fuels in energy intensive industries such as cement or energy production around Europe.

For every tonne of CO2e that we generate in our operations, we have identified 8 tonnes of CO2e that are avoided using our recovered outputs/products, and we intend to increase this to 10 tonnes over the next three years.

Enva operates across 33 facilities in the UK and Ireland, employing over 1,600 people. We are conscious that our own processes and transport of waste materials and recovered products contribute to our carbon footprint. We are constantly innovating and investing to minimise this impact – from the use of lower impact fuels and more efficient process solutions, to the minimisation of wasted effort and empty capacity in our logistics network. However, we are not perfect. Enva and the sector are still learning the full potential of waste materials. It is acknowledging this that keeps us moving forward, knowing that we are on a journey that is ripe with opportunity to better support customers on both sides of the waste equation.

All our activities are guided by the ‘Three Pillars of Sustainability’ – namely Environmental, Economic and Social. Referring to this framework provides a broader context for our activities, helping us to set meaningful targets for the future and enables us to run our business in a sustainable manner. This, in turn, supports our customers with reducing their own CO2 Scope 3 emissions, which are notoriously difficult to impact.

Enva have supported the University of Nottingham, to improve their sustainable waste management. Between August 2015 – July 2019 there has been:

- 714 tonne reduction in annual waste production,

- 1,671 tonne total waste reduction,

- 5,236 tonnes of waste recycled,

- 21% reduction in carbon emissions,

- 99% of waste diverted from landfill.

We hope that Enva’s first Sustainability Report helps you to understand what it is that makes us different. We look forward to updating you further in 2021 on our progress.

Read Enva’s full sustainability report here.

Read more about what happens to our waste.

No comments yet, fill out a comment to be the first

Leave a Reply