August 21, 2019, by Lexi Earl

The Future Food Beacon MakerSpace

We spoke to Principal Research Fellow Darren Wells, Dr Jonathan Atkinson, and Dr Michael Wilson about the new MakerSpace, located in the Plant Sciences building here on Sutton Bonington campus.

Tell us about the MakerSpace…

The Future Food Beacon MakerSpace is an innovation hub established to support experimental and outreach activities in Biosciences and elsewhere. It is a fabrication suite and workshop used to design, prototype and build small- to medium-sized experimental equipment, primarily supporting the integrated plant phenomics programme. We are open to supporting researchers across faculties in need of assistance.

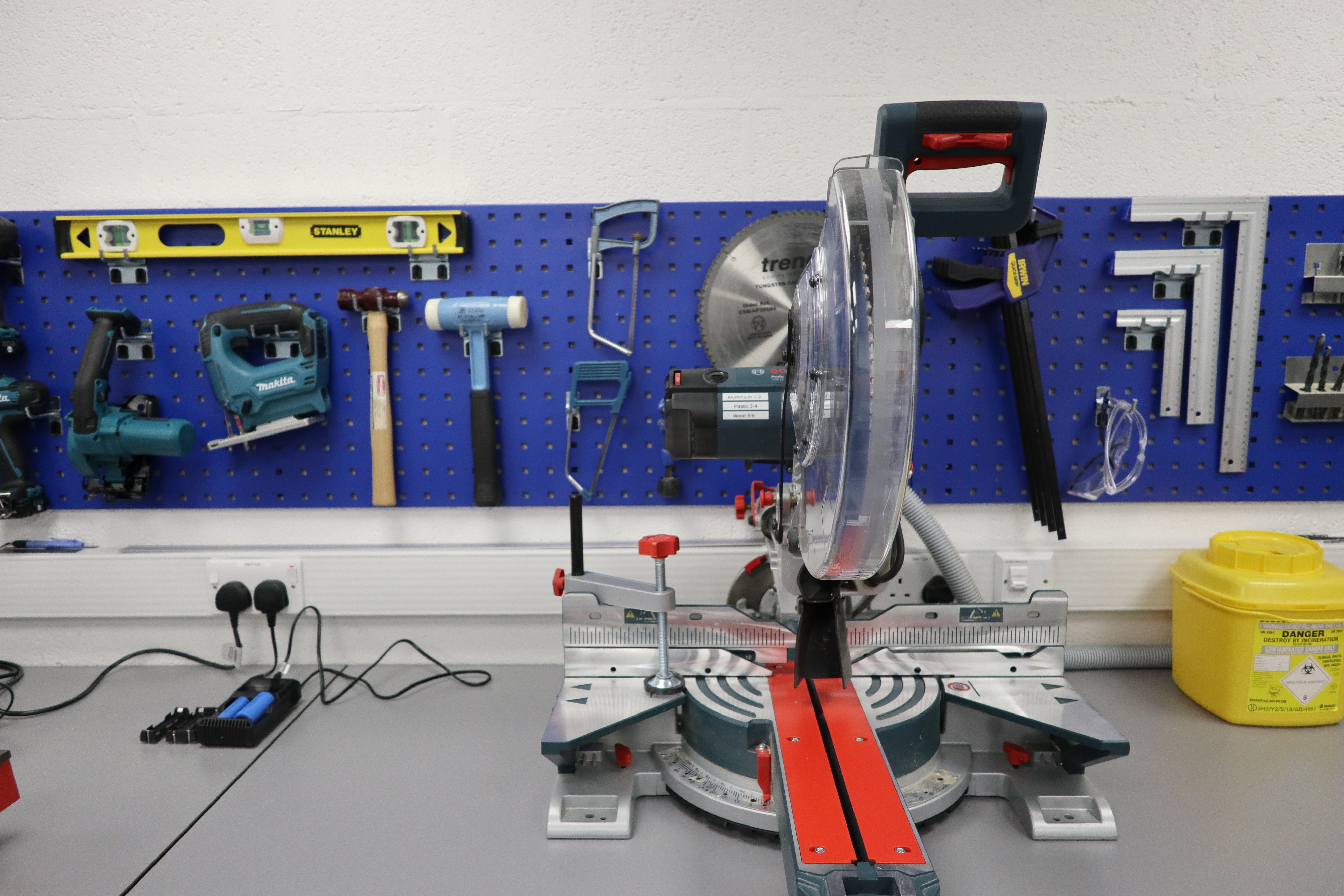

A selection of fabrication tools used in the makerspace

What kinds of equipment do you use/have?

The MakerSpace houses the existing workshop tools and equipment from the Wells Group at Sutton Bonington, and a range of new equipment funded by the Beacon, including 3D printers, hand and bench tools, and an electronics workspace. We also write software for robotics, data acquisition and sensor logging.

What sorts of things do you make?

Projects to date have included camera positioning systems, phenotyping robotics, wireless environmental sensors, outreach displays and microscope systems. We are open to all staff and students.

A thermal robot, designed by the MakerSpace

Plate robot, designed by the MakerSpace

How do the things you make feed into research?

Experiment-driven research often requires bespoke equipment matched to particular experimental needs. Designing the equipment as part of the experimental plan allows for more efficient use of (often) limited funds and increases the chance of useful data being generated. For example, we recently worked with a PhD student to design a microfluidic device to fit on a microscope and deliver precise volumes of media to growing plant roots.

What is the value of having this type of space in a Biosciences setting?

Using plant phenomics as an example, genetic studies require large numbers of measurements of plant traits, often images. Using robots to move either the cameras or the plants allows many more images to be taken per experiment. Custom-building the automation systems has two advantages: the kit is designed to generate exactly the data required, and the cost savings means that a larger proportion of the budget can be spent on the sensor systems, leading to higher value data.

3D printed nylon adapter for an active vision robot allowing both camera and gripper to be mounted together

Could you explain the process of making something?

A researcher will come to us with an idea for something that either doesn’t exist or is too expensive to purchase or commission. We will advise on feasibility and required resources and go through several brainstorming sessions to come up with a plan for a prototype. Depending on the complexity, we will build the final design based on the collaborative sessions, or advise on using the facilities for the researcher to build it themselves.

MakerSpace electronics: This project uses “internet-of-things” technology to modify laboratory balances for automated weight monitoring in long-term experiments. These low-cost devices are also being used to develop wireless environmental sensor networks

Have you had any disasters or particular successes?

To date, no real disasters – that’s the main advantage of low-cost prototyping – if the first version doesn’t work, the next one (or the one after that) will. A challenge is maintaining the balance between collaborative work and our own research programmes. Hopefully as more people use the MakerSpace independently, that balance will shift.

No comments yet, fill out a comment to be the first

Leave a Reply