November 3, 2020, by Richard Bates

Interview with Ian Maclean MBE of John Smedley Ltd

John Smedley Ltd is one of the oldest textile businesses in the world, having been first established at Lea in Derbyshire in 1784 by Peter Nightingale – Florence’s great-great-uncle. I recently interviewed Ian Maclean, its current managing director, about the company’s historical legacy, links with Nightingale, and its work during the pandemic, for which Ian has been awarded an MBE.

The John Smedley textile factory is one of the longest-standing in the world, having been in operation for 235 years. Founded by one of Florence Nightingale’s ancestors, it played a significant role in her life story, especially in developing her social consciousness by making her aware of the working and living conditions of industrial workers in her neighbourhood – the family had a house at nearby Lea Hurst. As a young woman Nightingale developed long-standing relationships with a number of mill families, and continued to look out for their welfare into her old age.

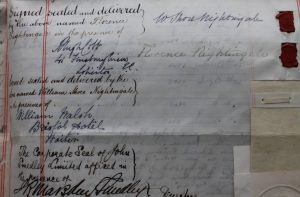

For Nightingale’s bicentenary in May 2020, John Smedley Ltd produced a limited-edition collection of garment designs in her honour, making use of Nightingale’s signature on the deed that transferred ownership of Lea Mills from the Nightingales to the Smedleys.

In May and June 2020, part of the workforce was redeployed to make PPE for local hospitals, GP surgeries and care homes. The firm produced 1000 sets of reusable medical scrubs and also provided support to the national Emergency Design Network to assist in the further manufacturing of PPE by individuals and small firms around the country.

RB: John Smedley is one of the oldest textile manufacturers in the UK. What does this legacy mean to the firm? What complications/challenges (if any) does it present?

IM: The history of the company and all its associated stories are really the foundation of who we are, and the brand as the consumer perceives it. In one sense, it provides a focal point for any number of conversations about why we don’t have so much manufacturing in Britain any more, how much we value manufacturing jobs, and (for the positive among us!) what this means for anyone who wants to devote their lives to rebuilding textiles in this country. We know we can’t re-create the old industry, but this doesn’t mean we can’t build an entirely new industry founded on a more sustainable mode of development. And several are trying. There are plenty of complications in being “the last of our kind”, not least the fact that we lack many of the services and ancillary industries and skills that were once abundant, and abundantly useful in keeping our factory operating at a level of fitness. This leaves us with a reliance on ourselves, and to a degree, a resultant amateurishness of approach. Nobody in our industry has cracked the problems of automation (as has been the case in engineering, for example), so we have become more a craft maker than a true manufacturer, with all the attendant costs. The good news is, I’m not disheartened by this as I feel there is enough ingenuity and graft around to get things moving in the right direction.

RB: How does the firm try to acknowledge, preserve and work with its historical legacy?

IM: Three years ago we decided to do exactly this by creating the John Smedley Archive Charitable Trust (“JSACT”) as the vehicle for doing so. JSACT now occupies the same site as John Smedley Ltd, and we have gifted all of our archive assets to it. The goal of the charity is to preserve knitwear artifacts, to research them and to tell the stories of John Smedley, the Company, the Family and all the staff who have ever work for us. This is quite an ambition, but the treasure trove of stories is wide and deep, thank goodness! Our Archivist and a group of volunteers have so far catalogued over 14,000 items in total, including the largest archive of knitwear garments in Europe, comprising around 9,000 pieces. They have also published five books to date, including histories of the staff who fought in World War I, diaries of travels to Australia in search of merino wool, and the links between the company and the Nightingale family. The archive has also starred in several TV programmes, including Who Do You Think You Are?, with the actor Charles Dance, who is distantly related to the Smedleys.

RB: What does the connection to the Nightingale family, and to Florence in particular, mean to the company?

IM: The link between the Company and the Nightingale family is relatively new news to me! It was only a couple of years ago when searching for an old written contract, that I learned the Company had purchased the freehold of its Lea Mills factory site from the Nightingales in 1894, and that Florence Nightingale herself had signed the contract on behalf of her family. This discovery, and the links with your research team, have led to a large body of work being done to reveal more of the story of the Nightingales when they lived at Lea Hurst, the family home that is only a very short distance from the Mill. Everything we have learned since is truly exciting: we can now see that Florence gained a lot of her earliest knowledge of how best to care for the sick and poor by visiting families living in the villages around her home (and our factory). We are indeed proud of the association and will continue to both research and tell the stories that arise over time.

The 1894 deed of transfer of Lea Mill from the Nightingales to the Smedleys, bearing Florence Nightingale’s signature

RB: Why did John Smedley seek to get involved with the response to the Covid-19 pandemic?

IM: We closed our factory at Lea Mills in March and April in response to a worsening sickness problem among our staff, and extensive supply chain disruption. During the closure period we made great efforts to make the working environment safe for people to return, and when we re-opened in May, it just seemed right at the time to attempt scrubs production because we knew shortages were happening in the NHS. Thankfully, a team of 10 volunteers was not difficult to assemble (they were all very willing) and were off and running!

A John Smedley worker making medical scrubs, 2020

RB: How much of a challenge was it to redirect the company’s efforts?

IM: Through our extensive industry contacts, we had a good idea of who was attempting to make scrubs in other parts of the country. The makers of fabric, of course, were inundated with orders, but we were able to secure a supply of fabric. We then received a very kind offer from a fabric cutting company in Nottingham to cut the required patterns for free – which was amazing. Finally, we had to undertake quite a bit of self-education and training to get the team into the swing of sewing and finishing the garments to the best standard (it’s John Smedley after all!). We also had to service and repair several sewing machines to make them operational. In the end, and all credit to the scrubs team, we turned out a very respectable 1,000 sets of garments in short order that were distributed for free to hospitals, GP practices and care home staff across Derbyshire.

Smedley scrubs being worn by an NHS worker

RB: Beyond the PPE effort in May-June, how else has the pandemic affected the factory and the company?

IM: – I remember reading early on in March that some of the top strategy consulting firms were predicting that companies in the fashion clothing sector would likely lose 30%-40% of their sales turnover in 2020, and not believing it. Well, they were almost spot on, and our sales turnover will be impacted to that magnitude. I cannot think that there has been such a sudden and extreme effect on John Smedley’s sales during its entire 236 year existence. We are really operating in new territory – and I must commend my colleagues for bearing up well in the circumstances. We immediately prioritised the cash position of the company and did everything we could to preserve cash at a time when predicting sales was impossible (all our London stores for example were closed for nearly 3 months). Many plans that we had to invest have been put on hold, and around 9% of the workforce have sadly had to be let go. Since the general economic “re-opening” in July, we have been monitoring sales from all markets very closely and trying to build a profitable business model for the next 2-3 years. The task is not yet done.

RB: What does the future look like for UK textile manufacturing?

IM: I truly believe that new innovators will build a new textile industry for the future, based on regenerative organic farming, zero CO2 emissions, circular business models and entirely new materials, to great effect. Where this leaves dinosaurs like us, I’m not sure – it’s adapt or die, I suppose.

Many thanks to Ian for taking part in this interview.

If you’d like to know more about the connections between Nightingale and John Smedley Jr, who ran the mill for much of Nightingale’s lifetime, see this piece by Steven Schmidt on our project blog.

No comments yet, fill out a comment to be the first

Leave a Reply