March 18, 2015, by Herve Morvan

Electrifying Aerospace: The Move towards a More Electric Aircraft

Last month, a large group from the University of Nottingham’s Institute for Aerospace Technology (IAT) attended the More Electric Aircraft Conference (MEA 2015) in Toulouse. It was an exciting event bringing together a range of skills and individuals to discuss the future of (commercial) aerospace and the forthcoming challenges and opportunities afforded by the use of more electrical systems within and across aircraft.

While it is clear that kerosene remains a fine, stable and effective source of energy for propulsion systems for long haul flights, it is important to note that for shorter missions, realistic opportunities exist for alternative energy options, including those that involve more electrical systems for power generation, apart from the traditional power-from-engine generation . This point was also made by Colin Smith, the Chief Technical Officer (CTO) of Rolls-Royce during the three day conference.

The current push towards more electric systems in aircraft is mainly due to the potential of overall improvements for aircraft efficiency, reliability and maintainability[1]. This progressive electrification serves to reduce or to remove the presence of the hydraulic, mechanical and the bleed air/pneumatic systems. A perceived advantage of the MEA concept is thus the improvement in the traditionally complex power distribution architecture in aircraft.

However, such a transformation of an aircraft’s systems increases the on board demand for electrical power by a considerable factor. For example, when moving towards more electric solutions, the starter-generator system needs to cater for the increased power demand, which is usually achieved by implementing a higher power starter-generator system. This automatically leads to an increase in the weight of the machine and its associated power electronics.

The main challenges for any novel aerospace electrical system are of course torque density and reliability. A particular aspect of the MEA initiative is the increased need of power electronics, which also need to comply with the robustness and reliability requirements (traditionally reliability of power electronics has been the weak link of the electrical system).

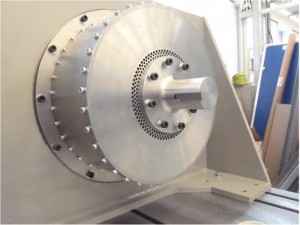

A perfect example of the push towards MEA is the concept of electrical taxiing. Implementing electrical motor drives into the landing gear of aircraft offers the prospect of ‘green’, electrical taxiing. The benefits of such a system were demonstrated by Safran – Messier Bugatti Dowty (S-MBD) and Honeywell with their Electrical Green Taxiing System (EGTS)[2] system at the Paris Airshow in 2013. A parallel activity between S-MBD and the PEMC group of the University of Nottingham involves the development of an alternative GT system[3]. This project is undertaken within the framework of the Systems for Green Operation ITD of the Cleansky JTI[4]. The main difference from the previous is that the developed system was required to achieve the same results without any mechanical advantages due to gearing this time. A direct drive motor, shown below with an impressive torque density of 54Nm/kg was consequently developed.

A perceived challenge with this direct drive (motor permanently connected to the wheel) is managing the system operation during take-off and landing. The motor above employs a permanent magnet (PM) technology which in simplistic terms means that the motor cannot be “switched-off” resulting in high levels of current being induced at the high speeds during take-off and landing. In order to propose and investigate solutions to this, an internal project within the framework of the Marie-Curie INNOVATE project is also in progress.

INNOVATE is an integrated programme bringing 13 PhD students together to progress a number of mechanical, propulsive, electrical and operational activities and incorporate them in a joint demonstrator by the beginning of 2017.

This INNOVATE project is being led by IAT Early Stage Researcher (ESR) Sara Roggia, who is responsible for the design and development of the electrical motor. Taking advantage of the multi-disciplinary nature of INNOVATE, an important input from another ESR, Michele Garibaldi will be required. Michele will bring his expertise in additive manufacturing[5], in order to propose reliable and effective techniques for the manufacturing of the highly complex rotor of an electrical motor.

While the above indicates a considerable push toward more electric systems on aircraft, this “electric revolution” is still however in its initial stages and relatively invisible in the industry. But more is to come, and this will soon become more apparent to the non-expert.

Take for example the E-FAN project led by Airbus Innovations Group. This aircraft first flew at the Farnborough International Airshow last summer and is propelled by two ducted fans powered by batteries. The aircraft has autonomy of 1h15. The propulsive action is solely that of a complex, rotating ‘propeller’ encased in a cylindrical nacelle. There is no jet. E-FAN2 is already in the planning and a number of distributed propulsion systems have appeared, often with a multiplicity of small ducted fans distributed on the aircraft or on its wing. Battery power is however not an appropriate solution at present. Batteries are limited due to storage capacity but also weight. Nevertheless this opens up the possibility of a hybrid system with e.g. a gas turbine housed in the body of the aircraft and used to power, mechanically or electrically, a series of external fans. Combining the strength of its propulsion, materials, manufacturing and power electronics, motor and control groups the IAT is well placed to take on such a challenge.

Looking beyond fuel power, there is also the prospect of using fuel cells to replace the more conventional gas turbine. As seen at the MEA2015 conference this is already being considered for the APU across a range of aircraft. The APU or auxiliary power unit is a devise (a gas turbine) used to provide power to start up the main engines and to run the aircraft electrics and avionics on the ground. Combining the fuel cell expertise from colleagues in the Energy Technology Research Institute (ETRI[6]) with that in the IAT, the scope is also there for us to contribute to this exciting challenge. Key issues remain naturally, such as how to design a fuel cell that can operate across a range of pressures and temperatures across the flight envelope, but this could maybe provide a solution towards a truly green flight in the future.

With contributions from Dr Michael Galea, Deputy Director, IAT.

References

[1] R. I. Jones, “The More Electric Aircraft: the past and the future?,” in Electrical Machines and Systems for the More Electric Aircraft (Ref. No. 1999/180), IEE Colloquium on, 1999, pp. 1/1-1/4

[2] http://www.safranmbd.com/spip.php?article411&lang=en

[3] M. Galea, T. Hamiti, and C. Gerada, “Torque density improvements for high performance machines,” in Electric Machines & Drives Conference (IEMDC), 2013 IEEE International, 2013, pp. 1066-1073

[5] http://www.nottingham.ac.uk/research/groups/3dprg/index.aspx

[6] http://www.nottingham.ac.uk/energy

I understand the underpinning concept of using a novel electric motor for ‘green taxiing’ is to reduce CO2 emission as an aircraft ground manoeuvres either before or after take-off. I further imagine that to move 70-80 tons of aircraft on the ground requires a heavy motor that must increase aircraft weight and thus cause more CO2 generation when in flight. Has thought been given to a system of driven cables running in just sub-surface runway channels that an aircraft would ‘latch’ onto for its ground movement and from which it would then ‘unhitch’ when in its desired position? These cables driven by large ground based motors would have potential economies of scale and obviate the need for each aircraft to carry its own electric motor. Not an original idea as anyone who understands how the cablecars in San Francisco operate will confirm.