September 29, 2016, by sustainablenottingham

Two leading carbon reduction projects at The University of Nottingham

Carbon Reduction Manager Martin Oakes shares some insights into two prominent carbon reduction projects at The University of Nottingham.

Medical School cooling system

Over the last 2 years we have installed 3 new efficiency cooling units for the Medical school. This provides chilled water to meet around 75% of the buildings cooling requirements. The chillers are electrically powered and use high efficiency compressors to minimise energy input. Along with improved chiller controls, this is expected to provide annual energy cost savings of £270,000 and carbon savings of 933 tonnes of CO2, equivalent to taking 183 cars off the road for a year.

The system has now operated successfully over the summer period. As a comparison with last summer (Jun-Aug), steam consumption for the Medical school has more than halved, resulting in a net saving of £103,765.

An additional £300,000 investment for a final chiller will mean the cooling requirements of the Medical School can be provided by new high efficiency plant. This unit will further increase resilience of the chilled water provision and save an extra £26,000 and 140 t CO2 per year, and is expected to be in use by the end of November.

Making Sutton Bonington greener

As part of a £1.35m energy efficiency project for Sutton Bonington, the main boiler house now accommodates two combined heat and power (CHP) units which produce heat and electricity for use at the campus.This upgrade delivers around 40% of the site’s electrical and heating demand.

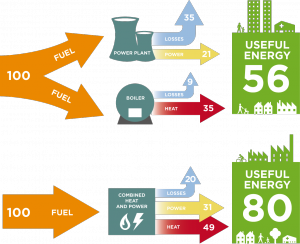

Conventional heat and electricity generation versus Combined Heat and Power (CHP).

CHP is the simultaneous production of heat and electricity from a single fuel source, in this case natural gas. It is effectively a small power station; but unlike the national grid, where the heat is not recovered, we are able to use the heat for our buildings. This enables large overall savings compared to separately purchasing gas and electricity.

The CHP units at Sutton Bonington consist of two reciprocating engines, allowing us to modulate the output and follow the energy use profile of the whole campus more closely. This maximises fuel costs and carbon savings, providing estimated reductions in annual energy bills of £260,000, and resulting in reducing the carbon footprint of the University by 1,150 tonnes.

Overall impact

Cumulatively, both of these energy efficiency projects are expected to deliver annual cost savings of over half a million pounds. They are expected to result in an annual carbon reduction of 2083 tonnes of CO2, which is equivalent to that of 160 average UK households.

To find out more about carbon reduction projects at the University of Nottingham, see our Carbon Management Plan 2010-2020.

No comments yet, fill out a comment to be the first

Leave a Reply